Production

Since 2003, YEN NAN Acrylic has been committed to providing stable and high-quality acrylic materials, and has earned ISO 9001:2000 certification. Our acrylic sheet production process is meticulously designed, ensuring that every step, from raw material selection to final quality inspection, guarantees that each acrylic sheet meets the demands of industries worldwide while maintaining exceptional quality. We offer our customers a worry-free experience with our products.

Manufacture Process of Casting Acrylic Sheets

1. Material Preparation

Our acrylic sheets are made from Methyl Methacrylate (MMA). We carefully select high-quality MMA raw material and add the necessary ingredients, such as hardeners, release agents, UV inhibitors, and pigments, to ensure the stability and durability of each batch, meeting your specific requirements.

2. Molding

The prepared raw material is injected into reinforced glass molds, and the four edges are secured with PVC strips to prevent leakage of the material during the injection process. Depending on the required thickness of the sheets, we carefully select the appropriate edge strips and clamps to precisely control the mold thickness, ensuring that every acrylic sheet meets perfect specifications and quality standards.

3. High-Temperature Polymerization

The molds containing the injected material are placed into a high-temperature water bath for curing treatment. After curing, the molds are then transferred to a high-temperature oven for the final polymerization process, ensuring that each acrylic sheet achieves optimal strength and durability, making it suitable for various applications.

4. Quality Inspection

After the acrylic sheets are removed from the glass molds, each sheet undergoes a comprehensive quality inspection. The inspection checks include thickness, weight, impurities, surface hardness, and color consistency. These stringent inspection standards ensure that every product meets YEN NAN Acrylic's high-quality requirements, delivering exceptional performance for both everyday and specialized applications.

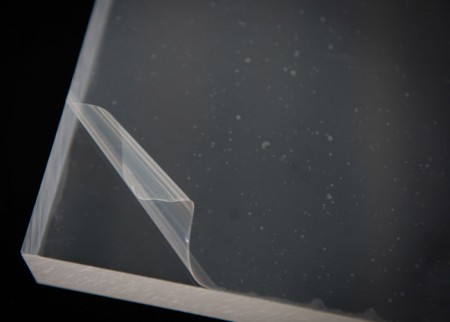

5. Warehousing and Packaging

The acrylic sheets that pass the quality inspection are professionally packaged to prevent damage during transportation. We also offer custom cutting services based on specific customer requirements, ensuring that the sheets are cut to the precise dimensions needed. All acrylic sheets are safely stored in our warehouse, ready for shipment at any time.

Production Process

- (1) Syrup Preparation

- (2) PVC Robber

- (3) Inject Syrup Into Glass Molds

- (4) Solidification

- (5) Quality Checking

- (6) Cutting Size

- (7) Warehouse

- (8) Loading Container

Package for Exporting Sheets

- Wood pallet place with drier and cover with PE Film by auto wrapping machine

- Wooden Pallet Package

- Metal Standing Package

- Metal Standing Package